Free Employee Productivity Calculator

Calculate Employee Productivity

Found our Free Employee Productivity Calculator useful? Bookmark and share it.

Graph: Productivity Change in the Non-farm Business Sector, 1947-2024

Data Retrieved From: https://www.bls.gov

What is Employee Productivity?

Employee productivity is a measure of how effectively an individual worker or group of workers completes tasks and contributes to the overall output of the organization. It is often quantified by comparing the amount of goods or services produced to the amount of resources, typically labor hours, utilized in the production process. Essentially, employee productivity reflects how well employees perform their roles in generating valuable outputs for the business.

Importance of Employee Productivity

Employee productivity is a crucial aspect of a business’s overall performance. Here are several reasons why it is important:

- Enhanced Profitability: Higher employee productivity leads to more output without a corresponding increase in costs, which can significantly boost a company’s profitability.

- Operational Efficiency: Productive employees help streamline processes, reduce waste, and optimize resource utilization, leading to more efficient operations.

- Competitive Advantage: Businesses with highly productive employees can innovate faster, respond more swiftly to market changes, and offer better products or services, providing a competitive edge.

- Employee Morale and Satisfaction: High productivity levels are often associated with a well-structured work environment, clear goals, and adequate support, which contribute to higher employee morale and job satisfaction.

Measuring Employee Productivity

Employee productivity can be measured using various methods, depending on the industry and the specific role of the employees. Common methods include:

- Output per Hour Worked: This is the most straightforward measure, where the total output is divided by the total number of hours worked. For example, if an employee produces 200 units of a product in 40 hours, their productivity is 5 units per hour.

- Revenue per Employee: This method involves dividing the total revenue generated by the number of employees. For instance, if a company generates $1 million in revenue with 50 employees, the productivity is $20,000 per employee.

- Goals and Objectives: In roles where outputs are not easily quantifiable, productivity can be measured by the achievement of specific goals or objectives. For example, resolving a certain number of customer service tickets within a given timeframe.

Factors Influencing Employee Productivity

Several factors can impact employee productivity, including:

- Work Environment: A positive, well-organized, and safe work environment can enhance productivity by reducing stress and facilitating better focus.

- Tools and Resources: Providing employees with the right tools, technology, and resources is essential for enabling them to perform their tasks efficiently and effectively.

- Training and Development: Continuous learning opportunities and professional development programs can help employees acquire new skills and improve their performance.

- Clear Goals and Expectations: When employees have clear, achievable goals and understand what is expected of them, they are more likely to be productive.

- Management and Leadership: Supportive and effective management practices, including regular feedback and recognition, can significantly boost employee productivity.

What is Productivity in Business?

Productivity in business measures how efficiently an organization converts inputs into outputs. It goes beyond simply quantifying the number of hours worked or tasks completed, focusing on the value and quality of the work produced. In essence, productivity reflects the efficiency of the processes and the effectiveness of the workforce in achieving desired outcomes.

Importance of Productivity in Achieving Business Goals

Productivity is a critical determinant of a business’s success. High productivity levels often correlate with increased profitability, competitive advantage, and sustainability. Here are some key reasons why productivity is crucial for achieving business goals:

- Revenue Growth: By maximizing productivity, businesses can produce more goods or services without a proportional increase in costs, directly contributing to revenue growth.

- Cost Efficiency: Enhanced productivity means better utilization of resources, leading to reduced waste and lower operational costs.

- Competitive Advantage: Companies with higher productivity can offer better prices, innovate faster, and provide superior customer service, setting them apart from competitors.

- Employee Satisfaction: When productivity initiatives are aligned with employee well-being, it can lead to higher job satisfaction, reduced turnover, and a more motivated workforce.

Relation Between Productivity, Efficiency, and Quality of Work

While productivity measures the quantity of output produced per unit of input, efficiency focuses on the quality and effectiveness of that output. The relationship between these concepts is crucial for a comprehensive understanding of business performance:

- Productivity: It quantifies how much work is completed, typically expressed as a ratio of output to input (e.g., units produced per hour).

- Efficiency: It assesses how well the work is done, emphasizing the quality and value of the output. High efficiency means producing superior outputs with minimal wasted resources.

- Quality of Work: This pertains to the standard of the outputs produced. It ensures that the outputs meet or exceed customer expectations, contributing to long-term business success.

Why Calculate Productivity?

Calculating productivity provides a range of benefits across different levels of an organization, helping to drive performance and achieve strategic objectives.

For Business Leaders:

- Strategic Planning: Understanding productivity levels aids in making informed decisions about resource allocation, growth strategies, and long-term planning.

- Financial Performance: By monitoring productivity, leaders can identify areas where efficiencies can be improved, ultimately leading to better financial results and profitability.

- Competitive Advantage: High productivity levels can distinguish a business from its competitors, allowing for better pricing, faster innovation, and superior customer service.

For Managers:

- Resource Management: Calculating productivity helps managers allocate resources effectively, ensuring that teams have what they need to perform optimally.

- Performance Monitoring: Regular productivity assessments allow managers to track team performance, identify bottlenecks, and provide targeted support and interventions.

- Employee Development: Managers can use productivity data to recognize high performers, offer feedback, and tailor training programs to address skill gaps.

For Employees:

- Clarity and Focus: Knowing productivity metrics helps employees understand their contributions to the organization, fostering a sense of purpose and direction.

- Motivation and Engagement: Clear productivity goals and regular feedback can boost employee morale and engagement, as employees see the impact of their work.

- Career Growth: Productivity measurements can highlight individual achievements, providing a basis for promotions, raises, and professional development opportunities.

Impact on Decision-Making and Performance Improvement

Calculating productivity is crucial for making informed decisions and driving continuous improvement within an organization.

- Data-Driven Decisions: Productivity data provides a factual basis for decision-making, reducing reliance on intuition or guesswork. This leads to more accurate and effective strategies.

- Identifying Inefficiencies: By analyzing productivity metrics, organizations can pinpoint inefficiencies in processes, workflows, and resource utilization, allowing for targeted improvements.

- Benchmarking and Goal Setting: Productivity measurements enable organizations to benchmark performance against industry standards or historical data, setting realistic and achievable goals.

- Performance Tracking: Ongoing productivity assessments help track progress towards goals, making it easier to adjust strategies and tactics as needed to stay on track.

Importance of Setting Clear Goals and Expectations

Clear goals and expectations are fundamental to driving productivity and achieving business success.

- Alignment and Focus: Well-defined goals ensure that all employees are aligned with the organization’s objectives, focusing their efforts on high-priority tasks that drive business results.

- Motivation and Accountability: Clear expectations provide employees with a sense of purpose and direction. When employees know what is expected of them, they are more motivated to meet or exceed those expectations.

- Performance Measurement: Specific goals make it easier to measure performance and productivity. With clear benchmarks, organizations can track progress and make data-driven adjustments to improve outcomes.

- Continuous Improvement: Setting goals and regularly reviewing them fosters a culture of continuous improvement. Employees and managers can learn from past performance, implement best practices, and strive for ongoing enhancements.

Common Misconceptions About Productivity Calculations

Quantity vs. Quality of Output

One of the most prevalent misconceptions about productivity calculations is the emphasis on quantity over quality. While it is essential to measure the amount of work done (e.g., units produced, tasks completed), it is equally important to consider the quality of the output. High productivity numbers can be misleading if the products or services produced are of poor quality.

For instance, an employee might produce a large number of items quickly, but if those items are defective or substandard, the overall productivity is not truly high. Therefore, productivity calculations should balance both quantity and quality to provide a comprehensive view of performance.

Contextual Differences Across Industries and Sectors

Another common misconception is the failure to account for contextual differences across various industries and sectors. Productivity measurements are not one-size-fits-all. What works in manufacturing may not be applicable in the service industry, and metrics used in sales may not be relevant for research and development.

- Manufacturing: Productivity might be measured by the number of units produced per hour.

- Service Industry: Metrics might include the number of tasks performed or customers served, with a focus on customer satisfaction.

- Sales: Productivity could be gauged by the number of deals closed or the revenue generated.

Importance of Accurate Data and Benchmarks

Accurate data and relevant benchmarks are vital for meaningful productivity calculations. Misconceptions often arise from using incomplete or inaccurate data, leading to flawed conclusions and misguided decisions.

- Accurate Data: Ensure that all input and output data are precise and comprehensive. Inaccurate data can skew productivity measurements and provide a false sense of performance.

- Relevant Benchmarks: Use industry-specific benchmarks to gauge productivity. These benchmarks provide a standard for comparison, helping organizations understand where they stand relative to their peers. Without appropriate benchmarks, it is challenging to determine whether productivity levels are satisfactory or need improvement.

The Productivity Formula

The basic productivity formula is a straightforward calculation used to measure how efficiently resources are utilized to produce output. The formula is:

Productivity = Total Output / Total Input

This formula helps organizations determine the efficiency of their operations by comparing the amount of output produced to the resources (input) used to generate that output.

Components: Output, Input, Productivity

Output:

- Output refers to the goods or services generated by the organization. It can be measured in various units such as the number of products produced, sales revenue, or tasks completed.

- Examples:

- Manufacturing: Number of units produced.

- Services: Number of tasks completed or customers served.

- Sales: Total revenue generated.

Input:

- Input represents the resources used to produce the output. This typically includes labor hours, raw materials, and capital.

- Examples:

- Labor: Total hours worked by employees.

- Materials: Quantity of raw materials used.

- Capital: Financial resources invested.

Productivity:

- Productivity is the ratio of output to input, indicating how efficiently the inputs are converted into outputs. Higher productivity signifies more efficient use of resources.

Examples and Practical Applications in Various Industries

Manufacturing:

- Scenario: A factory produces 10,000 widgets in a month using 2,000 labor hours.

- Calculation: Productivity = 10,000 widgets / 2,000 labor hours = 5 widgets per labor hour.

- Application: This metric helps the factory determine if there are ways to optimize production processes to increase the number of widgets produced per hour.

Service Industry:

- Scenario: A call center handles 1,200 customer support calls in a day with 20 employees working 8-hour shifts.

- Calculation: Total labor hours = 20 employees * 8 hours = 160 hours.

- Productivity: 1,200 calls / 160 hours = 7.5 calls per labor hour.

- Application: The call center can use this productivity measure to assess staffing levels and improve call handling procedures.

Sales:

- Scenario: A sales team generates $50,000 in revenue in one week with 5 sales representatives each working 40 hours.

- Calculation: Total labor hours = 5 representatives * 40 hours = 200 hours.

- Productivity: $50,000 / 200 hours = $250 per labor hour.

- Application: The sales manager can use this data to set performance targets and identify top-performing sales representatives.

Healthcare:

- Scenario: A clinic serves 300 patients in a week with 10 doctors working a total of 400 hours.

- Calculation: Productivity = 300 patients / 400 hours = 0.75 patients per hour.

- Application: The clinic can evaluate doctor schedules and patient handling processes to improve efficiency and patient care.

Retail:

- Scenario: A retail store generates $20,000 in sales in one day with 10 employees working 8-hour shifts.

- Calculation: Total labor hours = 10 employees * 8 hours = 80 hours.

- Productivity: $20,000 / 80 hours = $250 per labor hour.

- Application: The store can use this information to optimize staffing levels and improve sales strategies.

Detailed Methods to Calculate Productivity

Standard Productivity Formula

The standard productivity formula involves a simple division of output by input, providing a straightforward measure of efficiency.

Formula: Productivity = Total Output / Total Input

Example:

- Scenario: A factory produces 15,000 units in a month using 3,000 labor hours.

- Calculation: Productivity = 15,000 units / 3,000 labor hours = 5 units per labor hour.

- Application: This helps the factory determine if production processes are efficient and where improvements can be made to increase output per hour.

Objectives and Goals

This method calculates productivity based on the achievement of specific target goals, which is useful when outputs are not easily quantifiable.

Formula: Productivity = Achievement / Goal × 100

Example:

- Scenario: An IT help desk sets a goal to resolve 200 tickets each week and actually resolves 240 tickets.

- Calculation: Productivity = (240 / 200) * 100 = 120% of the goal.

- Application: This method provides insight into how well the IT help desk is performing against its targets and can help identify areas for further efficiency.

360-Degree Feedback

This method involves collecting feedback from peers and managers to evaluate an employee’s productivity, often using numerical ratings.

Example:

- Scenario: Employees and managers rate an employee’s productivity on a scale of 1-5. Ten peers participate, and the employee receives a cumulative score of 45.

- Calculation: Average rating = 45 / 10 = 4.5.

- Application: This qualitative method helps identify high-performing employees and those who may need additional support or training based on peer evaluations.

Revenue per Employee

This method divides the total revenue generated by the number of employees, providing a measure of how much revenue each employee contributes.

Formula: Productivity=Total RevenueNumber of Employees\text{Productivity} = \frac{\text{Total Revenue}}{\text{Number of Employees}}Productivity=Number of EmployeesTotal Revenue

Example:

- Scenario: A company generates $5 million in revenue annually with 100 employees.

- Calculation: Productivity = $5,000,000 / 100 employees = $50,000 per employee.

- Application: This method helps assess the overall efficiency and contribution of the workforce to the company’s financial performance.

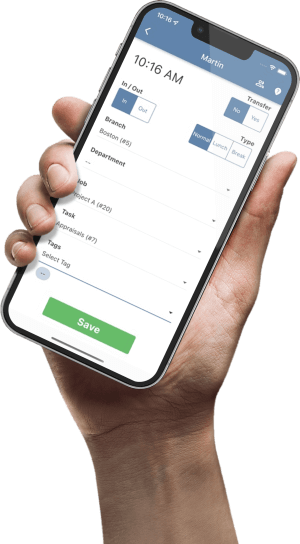

Productivity Management Software

Productivity management software automates data collection and analysis, offering detailed insights into productivity trends and factors influencing performance.

Benefits:

- Automated Data Collection: Software like TimeTrex automatically tracks employee activity, work hours, and outputs, reducing the need for manual data entry.

- Real-Time Analysis: Provides real-time data and analytics, allowing managers to make informed decisions quickly.

- Comprehensive Reporting: Generates detailed productivity reports at both individual and team levels, highlighting areas for improvement and success.

- Enhanced Accuracy: Minimizes errors associated with manual calculations and provides a more accurate picture of productivity.

Example:

- Scenario: Using TimeTrex, a company tracks employee productivity across various departments and identifies that the marketing team is consistently exceeding its goals.

- Application: Managers can use these insights to replicate successful strategies in other departments and provide targeted support where needed.

Advanced Productivity Calculations

Percent Changes and Indexes

Percent changes and indexes are useful tools for analyzing productivity trends over time. They help measure the rate of change and provide a comparative framework for assessing productivity improvements or declines.

Percent Changes:

- Explanation: Percent changes measure the change in productivity from one period to the next. They are calculated by comparing productivity levels between two periods.

- Formula: Percent Change = [(Productivity in Current Period – Productivity in Previous Period) / Productivity in Previous Period] × 100

- Example: If productivity increased from 50 units/hour last quarter to 55 units/hour this quarter:

- Percent Change = [(55 – 50) / 50] × 100 = 10%

Indexes:

- Explanation: Indexes measure the total percent change from a base period, set at 100. They help track productivity trends over time by standardizing comparisons.

- Formula: Productivity Index = (Productivity in Current Period / Productivity in Base Period) × 100

- Example: If the base period productivity is 100 units/hour and the current period productivity is 110 units/hour:

- Productivity Index = (110 / 100) × 100 = 110

Average Annual Percent Changes:

- Explanation: Measures the average rate of change in productivity over several years.

- Formula: Average Annual Percent Change = [(Productivity in Final Year / Productivity in Initial Year)^(1 / Number of Years)] – 1

- Example: If productivity grew from 100 units/hour to 150 units/hour over 5 years:

- Average Annual Percent Change = [(150 / 100)^(1/5)] – 1 ≈ 8.45%

Partial Factor Productivity

Partial Factor Productivity (PFP) measures the ratio of total output to a single input, providing insights into the efficiency of specific resource usage.

Formula: PFP = Total Output / Single Input

Example:

- Scenario: A factory produces $20,000 worth of goods using $8,000 worth of labor.

- Calculation: PFP = $20,000 / $8,000 = 2.5

- Application: This indicates that for every dollar spent on labor, $2.50 worth of goods is produced, helping identify areas to optimize labor efficiency.

Multifactor Productivity

Multifactor Productivity (MFP) considers multiple inputs to provide a comprehensive view of productivity.

Formula: MFP = Total Output / Subset of Inputs

Example:

- Scenario: A cross-docking operation processes $100,000 worth of goods using labor ($10,000), materials ($5,000), and capital ($15,000).

- Calculation: MFP = $100,000 / ($10,000 + $5,000 + $15,000) = 2.5

- Application: This method provides a holistic view of productivity by considering multiple resource inputs, helping optimize overall operations.

Total Factor Productivity

Total Factor Productivity (TFP) combines all resources used in production to measure the overall efficiency of an organization.

Formula: TFP = Total Output / Sum of All Inputs

Example:

- Scenario: A food processing plant produces $500,000 worth of products using labor ($100,000), materials ($200,000), and capital ($150,000).

- Calculation: TFP = $500,000 / ($100,000 + $200,000 + $150,000) = 1.25

- Application: By evaluating all resources, TFP provides a comprehensive measure of productivity, helping identify and address inefficiencies across the board.

Comprehensive Reporting Dashboard:

Example: A company uses a reporting dashboard to track TFP and its components, such as machine uptime, labor efficiency, and material usage. This dashboard helps managers monitor productivity in real-time, identify trends, and make informed decisions to improve overall efficiency.

Using the Employee Productivity Calculator

Step-by-Step Guide on Using the Calculator

Open the Calculator:

- Navigate to the Employee Productivity Calculator on the TimeTrex website.

Enter Total Output:

- Input the total value of goods or services produced in the designated field. This value should be a monetary figure representing the overall output.

Enter Total Input:

- Input the total number of labor hours or another unit of input used to produce the output. This field helps calculate the efficiency of resource usage.

Enter Number of Employees:

- Input the total number of employees involved in the production process. This helps determine individual employee productivity.

Click “Calculate Productivity”:

- Press the calculate button to compute the productivity values based on the input data.

Review the Results:

- The calculator will display the productivity results, including labor productivity and employee productivity.

Explanation of Each Input Field and Its Significance

Total Output:

- Definition: This is the total value of goods or services produced by the organization.

- Significance: It represents the overall production and helps determine how effectively the resources are being utilized to generate output.

Total Input:

- Definition: This is the total number of labor hours or another unit of input used in the production process.

- Significance: It measures the amount of resources expended to produce the total output, essential for calculating productivity.

Number of Employees:

- Definition: This is the total number of employees involved in the production process.

- Significance: It helps in calculating individual employee productivity, showing how much each employee contributes to the total output.

Examples of How to Interpret the Results

Labor Productivity:

- Scenario: Your company produced $80,000 worth of goods using 1,500 labor hours.

- Calculation: Labor Productivity = Total Output / Total Input = $80,000 / 1,500 hours = $53.33 per hour.

- Interpretation: This means that for every hour of labor, $53.33 worth of goods or services were produced, indicating the efficiency of labor usage.

Employee Productivity:

- Scenario: Your company produced $80,000 worth of goods with 30 employees.

- Calculation: Employee Productivity = Total Output / Number of Employees = $80,000 / 30 = $2,666.67 per employee.

- Interpretation: This means that each employee contributed an average of $2,666.67 to the total output, providing insight into individual performance.

Disclaimer: The content provided on this webpage is for informational purposes only and is not intended to be a substitute for professional advice. While we strive to ensure the accuracy and timeliness of the information presented here, the details may change over time or vary in different jurisdictions. Therefore, we do not guarantee the completeness, reliability, or absolute accuracy of this information. The information on this page should not be used as a basis for making legal, financial, or any other key decisions. We strongly advise consulting with a qualified professional or expert in the relevant field for specific advice, guidance, or services. By using this webpage, you acknowledge that the information is offered “as is” and that we are not liable for any errors, omissions, or inaccuracies in the content, nor for any actions taken based on the information provided. We shall not be held liable for any direct, indirect, incidental, consequential, or punitive damages arising out of your access to, use of, or reliance on any content on this page.

Trusted By

Trusted by 3.2M+ Employees: 21 Years of Service Across Startups to Fortune 500 Enterprises

Join our ever-growing community of satisfied customers today and experience the unparalleled benefits of TimeTrex.

Strength In Numbers

Join The Companies Already Benefiting From TimeTrex

Time To Clock-In

Start your 30-day free trial!

Experience the Ultimate Workforce Solution and Revolutionize Your Business Today

- Eliminate Errors

- Simple & Easy To Use

- Real-time Reporting

Saving businesses time and money through better workforce management since 2003.

Copyright © 2025 TimeTrex. All Rights Reserved.